AceGlueChecker

AceGlueChecker implements a close synergy between software applications, optical techniques and tricks of lighting, all meticulously branded AceLabs, to “see the unseen” and ensure total quality to the end customer.

The print jobs are in fact used as methods of thin film deposition in various fields.

For example in the food, AceGlueChecker is designed to perform control of the printing of the “cold seal”, a sealing system of food packages through a glue that is applied to the register during the printing stage. Question of verification which can’t be done with a common register control given the total transparency of the adhesive itself.

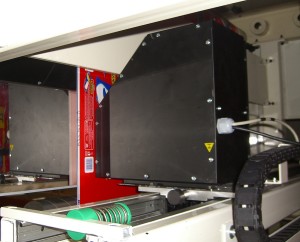

Glue printing (cold seal) control vision system

- Main features

- High resolution CMOS industrial matrix camera

- LED matrix strobo illuminator

- Full HD21.5 “touch panel PC

- Power supply in the electrical panel

- Version 1 optical group or version 2 optical groups (front / back)

- Motorized or manual handling

- Type of inspections

- Cold seal position check

- Print uniformity check

- Check for residues

- Cold seal alignment verification and correction

- Ideal for

- Thermoweilding machines for plastic films

- Flexographic machines

- Rotogravure machines

- Cut&Fold machines

also in: Italian

English

English