AceMACC 2.0

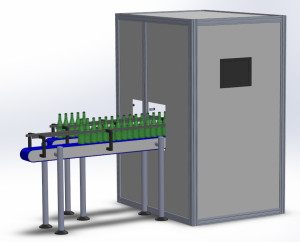

AceMACC 2.0 (Automatic Machine Control Capacity) is an automatic machine ideal for testing glass containers of all shapes. The machine is designed for hollow glass manufacturing companies that need to control the capacity on samples of various types of containers, with the aim of having a control on production.

AceMacc 2.0 has a modular structure and can be customized according to production needs. It consists of a vision chamber where the capacity control test of the containers takes place, through the filling with water and a vision system, thanks to the high modularity, it can be equipped with an input conveyor belt of variable size based on the number of molds of the plant, an output belt for maintaining the sequence, a rotating table or a direct reject.

The machine vision system is managed by a touch monitor that allows to view the acquired images of each individual container, processing inspection statistics and related data, with the possibility of connecting to the factory software.

Automatic machine for capacity/volume measurement of glass containers

- Main features

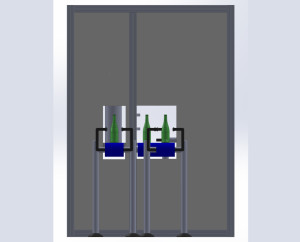

- Electric axis for containers translation

- High speed Cartesian filling robot with linear motors

- 3D vision cameras for high resolution centering

- Support for filling straw with retraction and emergency stop sensor

- Graduated filling straw with zero mark

- Centering for every type of glass and container

- Optical level sensor

- Optional output line: Conveyor belt / Table

- Statistics on the monitor

- Full HD monitor with keyboard / touch,

- Options and commands with simple icons

- Storage of all images in compressed images

- Remote assistance: the system is set up for remote support via a dedicated VPN connection.

- Types of inspection

- User fill height capacity measurement

- Brimfull capacity measurement

- Test report generation

- Advantages

- 3D vision system with high resolution cameras for container position recognition

- Possibility of connection to factory management software

- Intuitive operation thanks to the simple and touch interface

- Reports generated according to industry regulations

- Production under control and satisfied end customers

- Low-cost life cycle

also in: Italian

English

English