AcePrintChecker

Our system is designed to meet the need for comprehensive control during the printing process, ensuring precise inspection of the entire print format and detailed archiving of all defects detected during production.

AcePartTracker

Vision system for the traceability and serialization of products. Composed of a vision module for scanning products with the most complex shapes and code readers along the line for reading boxes and pallets, digitalizing and centralizing data in a database.

AceFoilChecker

Vision system for the inspection for tapes of composite materials. The system uses one or more high resolution linear cameras and two special linear light sources to frame even the most difficult defects to find.

AceFilmInspector

Vision system for the inspection of plastic films, highly adaptable in automatic lines/machines: extrusion, thermowelding, cutters and rewinders. The system detects insects and production residues.

AceFormChecker

Vision system for the 100% print quality control. The system performs quality checks, congruency and correctness of variable data on the printing.

AceDigitalStrobe

Vision system for viewing and inspecting defects of the printing. Ideal for linear, gravure and flexo machines (ex. packaging printing, decorative prints, wallpaper printing and label printing).

AceGlueChecker

Vision system for the inspection of "cold seal" printing and glue for sealing of packaging.

AcePrintTune

Vision system for the inspection of the alignment of printing cylinders on flexo and rotogravure machines.

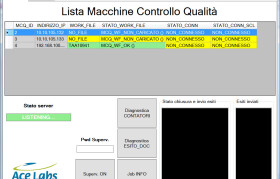

AceSRM

Software application for inspection data management centralization on printing and converting applications. The software is compatible with most PCs and operating systems.

AceMACC 2.0

Automatic machine for the capacity/volume measurement of glass containers. The machine performs filling tests checking the capacity of bottles and jars of different sizes, up to 36 with automatic cycle.

AceMACCLite

Semiautomatic laboratory machine for the automatic capacity/volume measurement for containers of different materials such as Glass, PET and Cans. The machine allows to reduce human error in performing tests, improving repeatability and objectivity.

AceSilkScreen

Vision system for the inspection of silk screen printing on various materials and formats, on plane sheets or round surfaces.

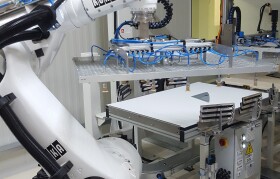

AceSDC

Automatic sorting machine for the inspection of small parts. The integrated vision system allows to perform different checks (measurement, surface inspection, and reading of codes) dividing the them into good/waste.

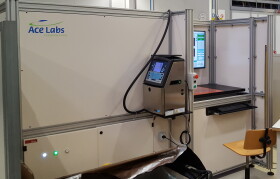

AcePlanarInspector

Automatic inspection machine for cut sheets of different sizes and shapes. The machine is loaded and unloaded by the operator and is able to mark the sheet with good/waste text.

English

English